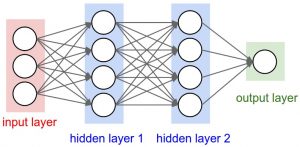

Neuronal Networks need compute power. You can buy cloud time, but that’s rather expensive. So we need a hardware update.

Our only desktop computer is old and was never intended to be a good in floating point simulations. Ever with the limited CAD work I do, you feel it’s age. A new one should be good for single thread applications, and machine learning supported by a GPU.

And it will run on Linux!

Setup

- CPU: Intel Core i9 7900x

Machine Learning doesn’t require a very fast CPU, but some of the other, single threaded Linux applications do. - Motherboard: ASRock Fatal1ty X299 Gaming K6

That was a tough one. The fast boards, with a reasonable price and the support for multiple GPUs are the gamer boards. But I don’t need fancy lighting. And I don’t need Wifi, we have wired Ethernet. And it has to support Linux only. - RAM: 4 x 8 GByte

I don’t need 32 GByte for a start, but I wanted to use all 4 memory banks for speed. - Disk: 1TByte SSD

- GPU: Nvidia GeForce GTX 1080 Ti or RTX 2080 Ti

It has to be Nvidia because of the CUDA support. I was targeting the GTX 1080, but just now Nvidia has announced the RTX 2080. I will wait a month to see what the reviewers say, and how the price of the GTX 1080 Ti develops. For now I have bought a cheap Nvidia to set up the system. - CPU Cooler: Noctua NH D15

- Power Supply: BeQuiet 700 W ATX

- Casing: tbd, I’d like to get another LIAN LI casing, they are nice.